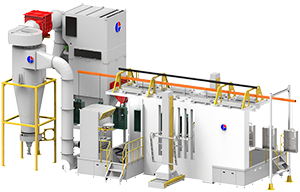

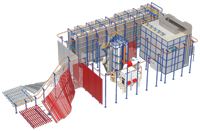

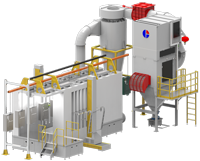

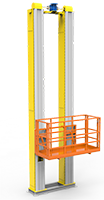

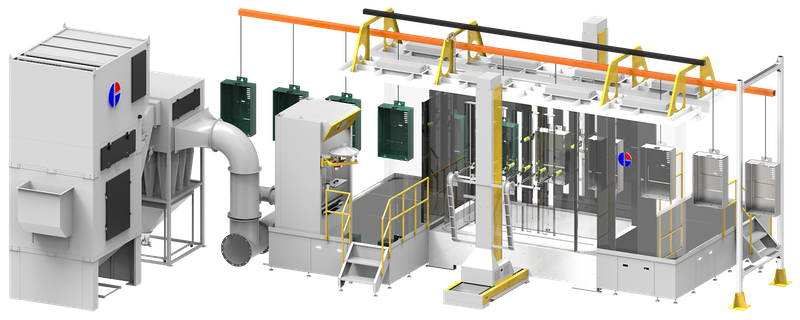

Panoramic presentation of the characteristics of the glass powder room

1. Junhe pioneered a new powder room structure. The glass does not bear any external force, and the overall powder room structure is solid and solid.

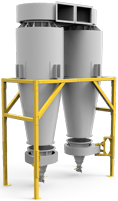

2. The large cyclone separation technology with a single separation rate of up to 98% saves powder;

3. The glass powder room is equipped with high-transmittance double-layer sandwich tempered glass. Even if the tempered glass encounters severe external impact and breaks, it can ensure that the glass fragments will not fall and hurt people.

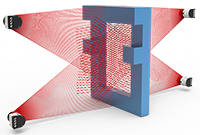

4. Compared with the traditional engineering plastic powder room, the extremely high transmittance brings a good visual experience. People standing inside can feel that the space is more open, and the external light source can enter the powder room, making the spraying environment brighter.

5. The transparent characteristics of the glass make the working conditions of the entire powder room visible. People can see the workshop conditions outside the powder room in the hand-spraying platform, and people outside the powder room can also see the specific use conditions of the powder room, such as whether there is manual replenishment, whether the spray gun is discharging powder, whether there are workpieces passing through the powder room, etc.

6. Compared with the traditional engineering plastic powder room, the glass surface is smoother and less likely to stick to powder. The spraying environment is more comfortable.

7. The bottom of the spray room is equipped with an automatic flap device or an automatic cleaning air knife, and there is almost no powder retention at the bottom of the spray room;

8. The powder supply center can realize the fully automatic circulation of powder. When cleaning the spray room, the powder supply center will automatically clean the powder suction pipe, powder pump, powder pipe and spray gun;

9. It can be equipped with a new powder automatic adding device:

10. The powder supply center adopts a powder-saving design to minimize the waste of powder in fluidized spraying

11. It can be equipped with an automatic cleaning device for the spray gun body;

12. It uses high-quality and long-life nano-film filter elements, and the filter element life can be up to several years; the nano-film filter element can capture dust above 0.1 microns without wasting any powder. At the same time, the filtered gas becomes clean air and can be directly circulated in the factory;

13. A variety of bottom recovery methods are available, suitable for various types of workpieces.