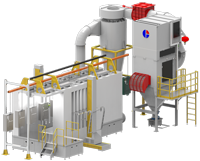

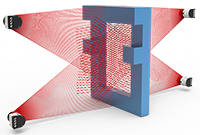

Features of gap grating:

1. Effectively improve the quality of spraying;

2. Automatic spray gun positioning and switch gun setting improve the spray quality and reduce powder waste in the recovery system

3. Reduce empty spraying, save paint, and reduce equipment wear;

4. Automatic opening/closing of the spray gun can reduce overspray powder, reduce powder wear, and reduce equipment maintenance costs;

5. When there is no workpiece or the gap between the workpieces is large, the spray gun will automatically close in turn, so that there is spraying when there is a workpiece and no spraying when there is no workpiece, which is called gap control. The switch of the spray gun can set the advance amount and lag amount, and the working time of the spray gun can be automatically triggered according to the size of the workpiece, thereby saving powder output and improving recovery efficiency.

6. The product is located in the spraying area, which greatly reduces overspraying and operating costs;