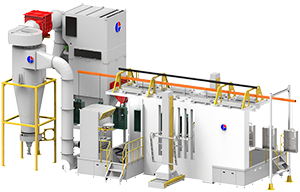

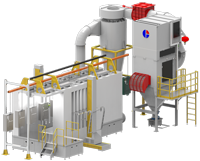

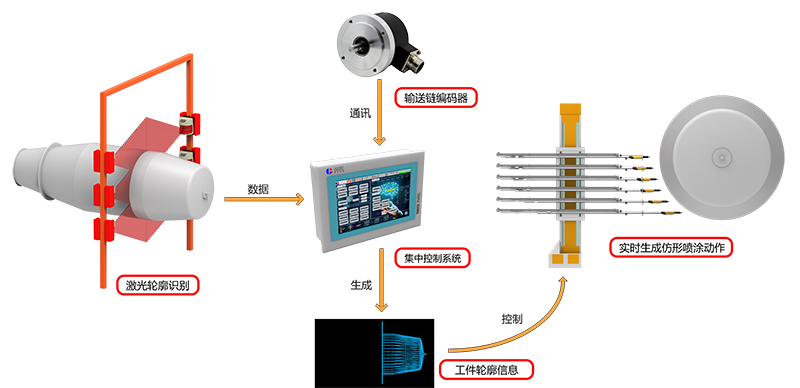

System Introduction:

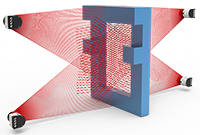

A laser scanner is used to record the contour information of the workpiece to be sprayed and after computer processing, it is provided to the PLC, which then drives the servo controller to drive the corresponding spray gun to perform contour spraying, thereby achieving the maximum degree of automated spraying.

Project Introduction:

Features and Advantages:

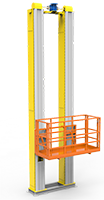

• Improved spraying quality;

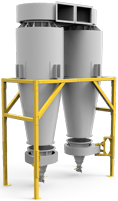

• Reduced powder waste in the recovery system;

• Detected the length, width and height of the workpiece;

• Scanned the 3D shape of complex workpieces;

• Can communicate through Powder Pilot HD;

• The product is located in the spraying area, which greatly reduces overspraying and operating costs;

• The servo controller is driven by the PLC to drive the corresponding spray gun to move independently.

The laser scanner is installed about 3m in front of the entrance of the spraying room to detect the outer contours of the left and right sides of the workpiece passing through. After the accumulation chain enters the laser detection range, no differential mechanism can be added. It must be ensured that the laser detection position is consistent with the speed of the hanging chain in the spray room.