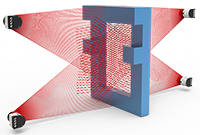

The design concept of INOGUN M is based on providing the best powder coating and providing the best performance for the operator: very balanced, soft low-voltage cable and powder hose, soft touch and flexible triggering. The powerful high-voltage unit, together with the high-voltage controller, can produce a high hugging effect on large parts (diameter 500mm/20 inches) and penetrate the recessed areas of the workpiece. This greatly improves the utilization of powder, shortens the spraying time and significantly reduces the operating costs of the equipment.

The control of INOGUN M is done by the Inobox controller with a very clear and easy-to-understand user interface. When integrated in an automatic powder room, the control of INOGUN M can also be done by the built-in Inocontoller. Both Inobox and Inocontoller are the control center of Inogun M, performing High pressure and air flow control: current, electrode blowing, injection and dilution air. Powder saving and energy saving are at the core of the development and manufacture of spray guns to reduce waste emissions, improve production efficiency and the surface quality of the coating. TEC5 technology (Total Energy Control) ensures self-regulation of the electrostatic charge, taking into account the changes in powder flow and part distance to optimize powder transfer efficiency and finished product quality.

INOGUN M is available in different kits depending on the needs of the powder coating process. As the main spray gun for powder coating, INOGUN M can be supplied with powder buckets or from powder boxes on a vibrating table. As a pre-touch gun or manual touch-up gun in an automatic powder booth, INOGUN M can easily achieve high powder coating quality on components. INOGUN M can also be used for non-destructive testing applications.