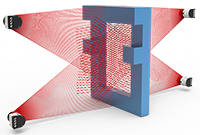

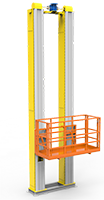

Inocart VT is suitable for spraying powders such as polyester, epoxy or acrylic, with a feed volume of 20 kg (44 lbs)/box. The vibration table liquefies the powder and allows the powder pump to quickly deliver the powder to the manual spray gun through the hose. Saving powder and energy have always been the core of the research and development and manufacturing of spray guns to increase productivity, shorten production time, and improve the surface quality of the coating. TEC5 (Total Energy Control) technology ensures self-regulation of electrostatic charge - always considering powder flow and distance to the part - to optimize powder transfer efficiency and spray surface quality.

Inocart VT has a quick cleaning option, easy to clean and convenient to manage. The powerful high-pressure unit cooperates with the high-pressure control system to produce better environmental protection and penetration effect, suitable for spraying large workpieces (diameter 500 mm/20 inches) and confined areas. This not only reduces the cost of the equipment, but also improves the utilization of powder and shortens the powder spraying time. Inobox is the controller of Inogun M, performing high pressure and airflow control: high pressure, current, electrode blowing and injection, and dilution.

The powder hose and cable are available in two different lengths, 6 m (19.7 ft) and 12 m (39.4 ft), for processing small or large workpieces. The Inocart VT can be used as a primary tool for powder spraying or as an additional device for pre-coating or touch-up painting to achieve results that exceed expectations.