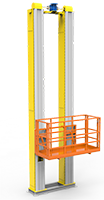

Inocart NDT is designed for non-destructive testing process applications and has been widely used in the aerospace field. The powder is finely applied in a uniform coating with visible cracks. To obtain a uniform film thickness, the CSV230 pressure tank can continuously feed the powder gun to meet the application to ensure the powder coating thickness. The system is compact and stable, with a low center of gravity and large rear wheels, which ensures easy movement and stable operation of the trolley in any situation.

Saving powder and energy have always been the core of the research and development and manufacturing of spray guns to increase productivity, shorten production time, and improve the surface quality of the coating.

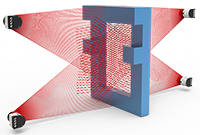

TEC5 (Total Energy Control) technology ensures self-regulation of electrostatic charge - always considering powder flow and distance to the part - to optimize powder transfer efficiency and spray surface quality.

The pull rod design on the Inocart NDT set powder tank can quickly adjust the powder flow, which is simple to use and easy to manage. The powerful high-pressure unit cooperates with the high-pressure control system to produce better environmental protection and penetration effect, suitable for spraying large workpieces (diameter 500 mm/20 inches) and confined areas. This not only reduces the cost of the equipment, but also improves the utilization rate of powder and shortens the powder spraying time. Inobox is the controller for Inocart NDT and performs high pressure and gas flow control: high pressure, current, electrode blowing and injection, and dilution.