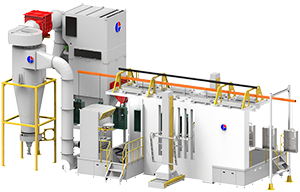

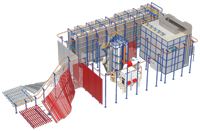

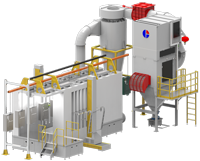

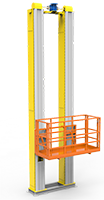

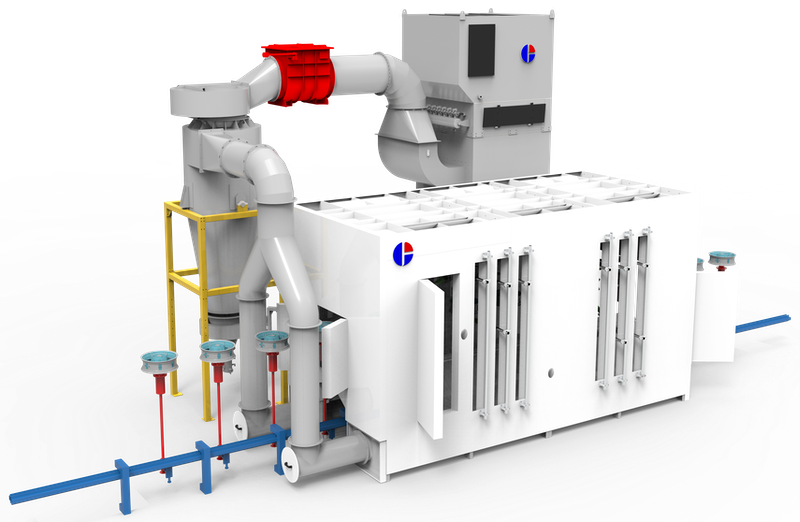

Features of VWH wheel-mounted floor-type spray booth system

1. The sandwich spray booth body and bottom plate are made of anti-static imported engineering plastics to ensure a high powder application rate, minimum powder retention and the fastest spray booth cleaning speed;

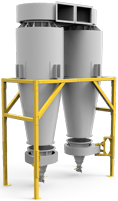

2. The large cyclone separation technology with a single separation rate of up to 98% saves powder;

3. The powder supply center can realize the fully automatic circulation of powder. When cleaning the spray booth, the powder supply center will automatically clean the powder suction pipe, powder pump, powder pipe and spray gun;

4. It can be equipped with an automatic new powder adding device;

5. The powder supply center adopts a powder-saving design to reduce the powder wasted by fluidized spraying. to the lowest;

6. Use high-quality and long-life nano-film filter elements, the filter element life can be up to several years; nano-film filter elements can capture dust above 0.1 microns, without wasting any powder, and at the same time, the filtered gas becomes clean air and can be directly circulated in the factory;

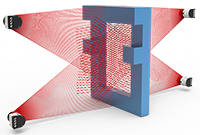

7. The double recovery air duct structure is adopted on both sides of the transmission track of the spray room, and the powder generated by spraying will be recovered by the air ducts on both sides;

8. The interior is all adjustable fixed spray guns, and the spraying range of the spray gun can be adjusted independently according to the shape of the wheel hub, so that the inner cavity and the outer side of the wheel hub are evenly covered with the spraying area