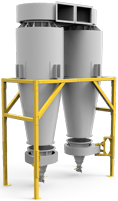

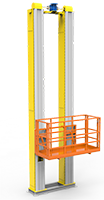

Features of PP06 dense phase large-capacity powder pump:

1. High conveying efficiency, small powder delivery gas volume, no dust overflow.

2. Large powder delivery volume, up to 6KG/Min.

3. With automatic cleaning function, color can be changed quickly. Adaptable to any existing equipment,

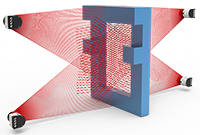

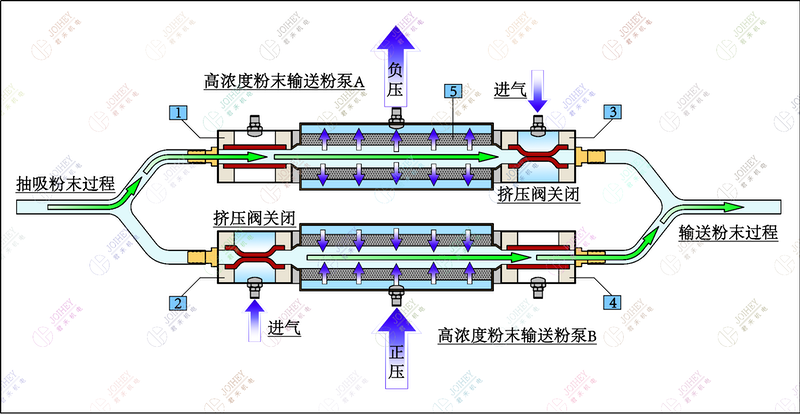

Powder suction process:

In the powder pump (A), due to the negative pressure generated by the vacuum generator, a vacuum is formed, and the vacuum causes the powder to be sucked into the powder pump (A), and then the powder is filtered and separated through the filter element (5) in the powder pump (A). At this time, the extrusion valve (1) on the input side of the powder pump (A) is in the open state, and the extrusion valve (3) on the output side is in the closed state.

Powder delivery process:

In the powder pump (B), due to the positive pressure formed by the compressed air delivered to the vacuum generator, the powder is squeezed out of the powder pump (B) due to the increased pressure. At this time, the extrusion valve (2) on the input side of the powder pump (B) is in the closed state, and the extrusion valve (4) on the output side is in the open state.

Working process of powder pump:

The working process of powder pump is to transport powder through the process of sucking powder and the process of conveying powder. The process of sucking powder and the process of conveying powder are carried out alternately between powder pump (A) and powder pump (B).