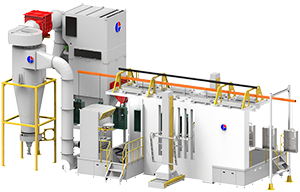

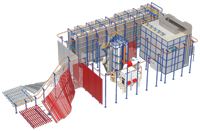

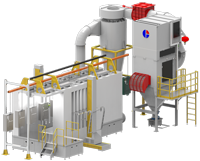

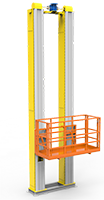

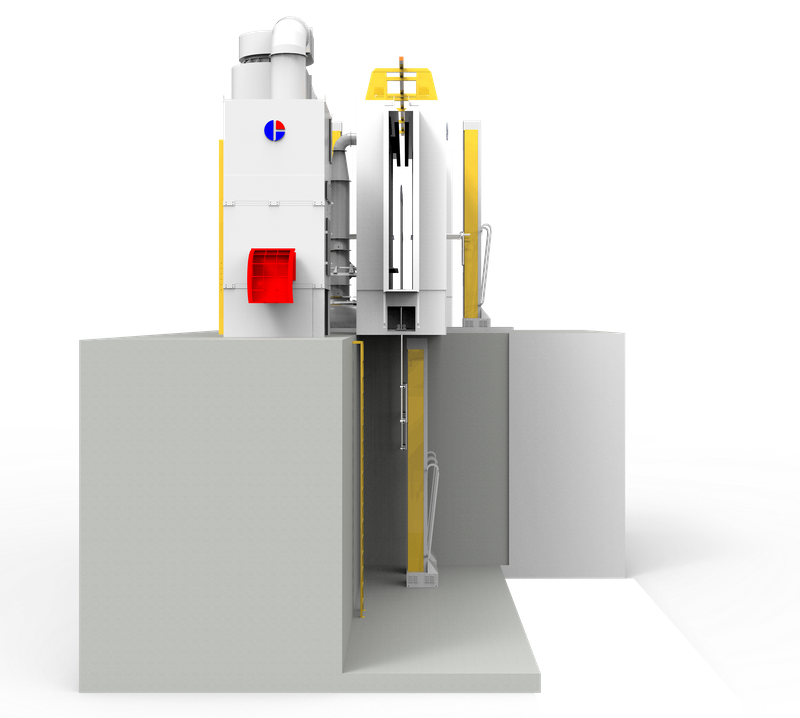

Features of LOP pipeline internal and external spray booth system

1. Anti-static imported engineering plastics are used to make the sandwich spray booth body and bottom plate, ensuring a high powder application rate, minimum powder retention and the fastest spray booth cleaning speed

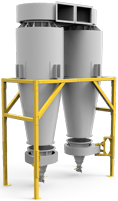

2. Large cyclone separation technology with a single separation rate of up to 98% saves powder;

3. The bottom of the spray booth is equipped with an automatic flap device or an automatic cleaning air knife, and there is almost no powder retention at the bottom of the spray booth;

4. The powder supply center can realize the fully automatic circulation of powder. When cleaning the spray booth, the powder supply center will automatically clean the powder suction pipe, powder pump, powder pipe and spray gun;

5. New powder can be configured to automatically Adding device:

6. The powder supply center adopts a powder-saving design to minimize the powder wasted in fluidized spraying

7. The automatic cleaning device for the spray gun body can be configured;

8. The high-quality and long-life nano-film filter element is used, and the filter element life can be up to several years; the nano-film filter element can capture dust above 0.1 microns without wasting any powder. At the same time, the filtered gas becomes clean air and can be directly circulated in the factory;

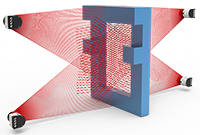

9. The bottom of the powder room is built-in with a spraying mechanism, and the sprayer can spray up and down through the bottom of the powder room, effectively spraying the inner cavity of the pipeline while avoiding powder overflow.